COLORANT COREA

REQUEST FOR TECHNICIAL SUPPORT AND CONSULTATION

REQUEST FOR TECHNICIAL SUPPORT AND CONSULTATION

Organic pigments

Colorant Corea Co., Ltd. was established in 2000 under the philosophy of “win-win management based on respect for mankind and customer satisfaction.”

It is a company that shapes the future of the color in- dustry and puts the environment and people first, contributing to coloring the world village with bright and vivid colors and enriching people’s life.

Based on our professional and excellent field experience, we are rewarding our customers for their trust and expectation by providing the best service and reliable products to meet customers’ needs.

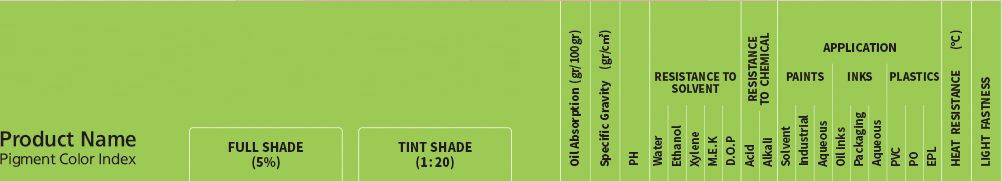

This catalog provides the representative characteristics of organic pigments for PAINT, INK and PLASTIC.

Applicable fields are shown in this catalog, but they are only general instructions. We recommend using the products after evaluating them yourself.

We at Colorant Corea Co., Ltd. hope that we can help you and we ask for your cooperation.

- icon01

- icon02

- icon03

- icon04

- icon05

Test Methods

-

Oil Absorption

It is determined by the Spatula Rub-Out method using boiled Linseed oil on a glass plate.

It is expressed as the amount of linseed oil per 100g of pigment.(gr/100gr) -

Specific Gravity

It is determined using specific gravity cups and ex- pressed in units of gr/c㎥. Ethanol is used to remove air from the pigment particles.

-

pH

Pour 0.5g of the pigment into a triangular glass flask, add 10ml of methanol and 50ml of distilled water, cover it with a stopper, and shake well. After 30 minutes, the pH value of the filtrate is measured by the pH meter.

-

Resistance to Solvent

Put 0.2g of pigment in a folded filter paper, immerse in 20ml of solvent for 24 hours and then remove, and finally label the degree of solvent bleeding as 1~5.

-

Resistance to Chemical

Put 2g of pigment into a test tube, add 30ml of 2% HCI or 2% NaOH solution, and stir for 30 minutes. The degree of coloration of the filtrate is marked by grades 1~5.

-

Heat Resistance

0.4g of pigment is mixed with 200g of p.p (Homo Polypropylene) and tested at injection molding with increasing duration at constant temperature.

-

Light Fastance

The test specimens of full shade and tint shade are exposed to Xenon lamp using Weather-O-Meter, and the degree of color change is graded 1 ~ 8 using Blue Wool Scale.

-

Assessment

Resistance to Solvent & Chemical

Scale 1 : Drastic Bleeding ~

Scale 5 : No Bleeding

Light Fastness

Scale 1 : Poor ~

Scale 8 : Excellent -

Recommendation

● Major Use

○ Other Potential Uses

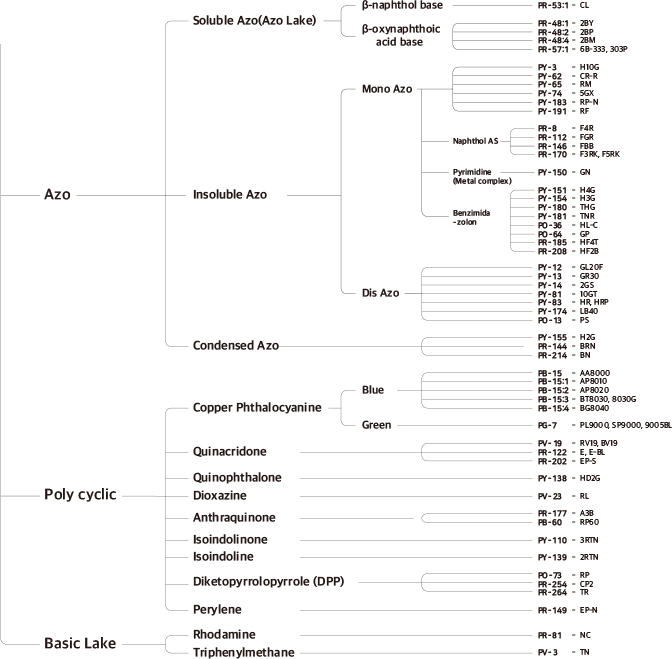

Classification of Organic Pigments

Organic Pigments

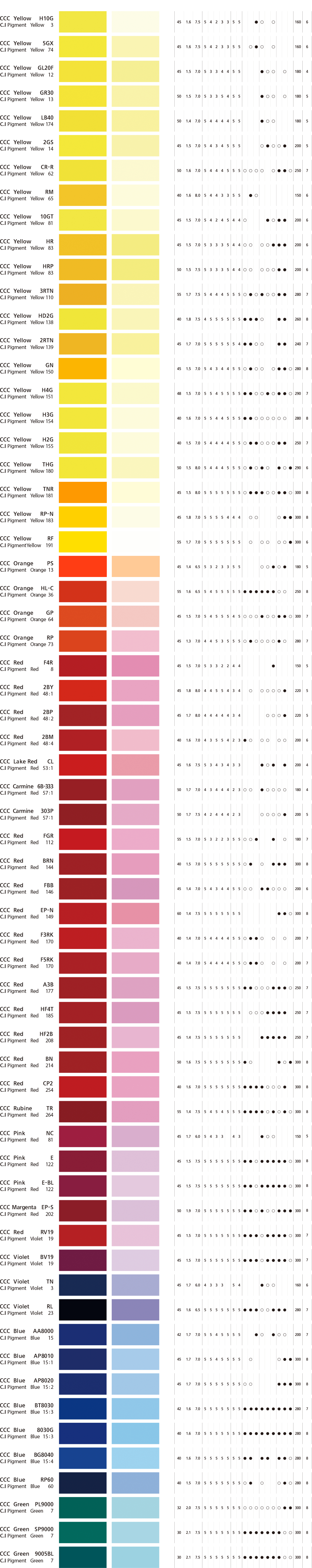

Color Index of Organic Pigments

Colorant Corea Pigments & Dispersions

Colorant Corea Pigments & Dispersions